This STS screen has been delivered to a French company, here it will be used to separate composted material from any unwanted pieces.

Each star has been equipped with a special “hammer” to clean the shaft and prevent any blockages. screens like these can handle relatively high volumes of material.

A GBS screen has been delivered to South Africa. The GBS screen uses hardened steel discs to break glass and separate it from the (coarse) infeed material.

This OCC screen has been delivered to South Africa. An OCC screen is able to separate OCC (Cardboard) from the infeed stream. Infeed can be plastic/paper but may also contain glass or cans.

This STS screen with its large starts is used to separate spent mushroom compost from branches or roots. This screen is also equipped with the special “hammers” to prevent blockages of the screen.

Recently, a remarkable conveyor belt system was delivered to the United Kingdom, designed to facilitate the disposal of large truck tires in a shredder.

With its robust construction and precise engineering, this conveyor belt not only streamlines the tire disposal process but also contributes to sustainable waste management practices, demonstrating the importance of innovative solutions in addressing environmental challenges.

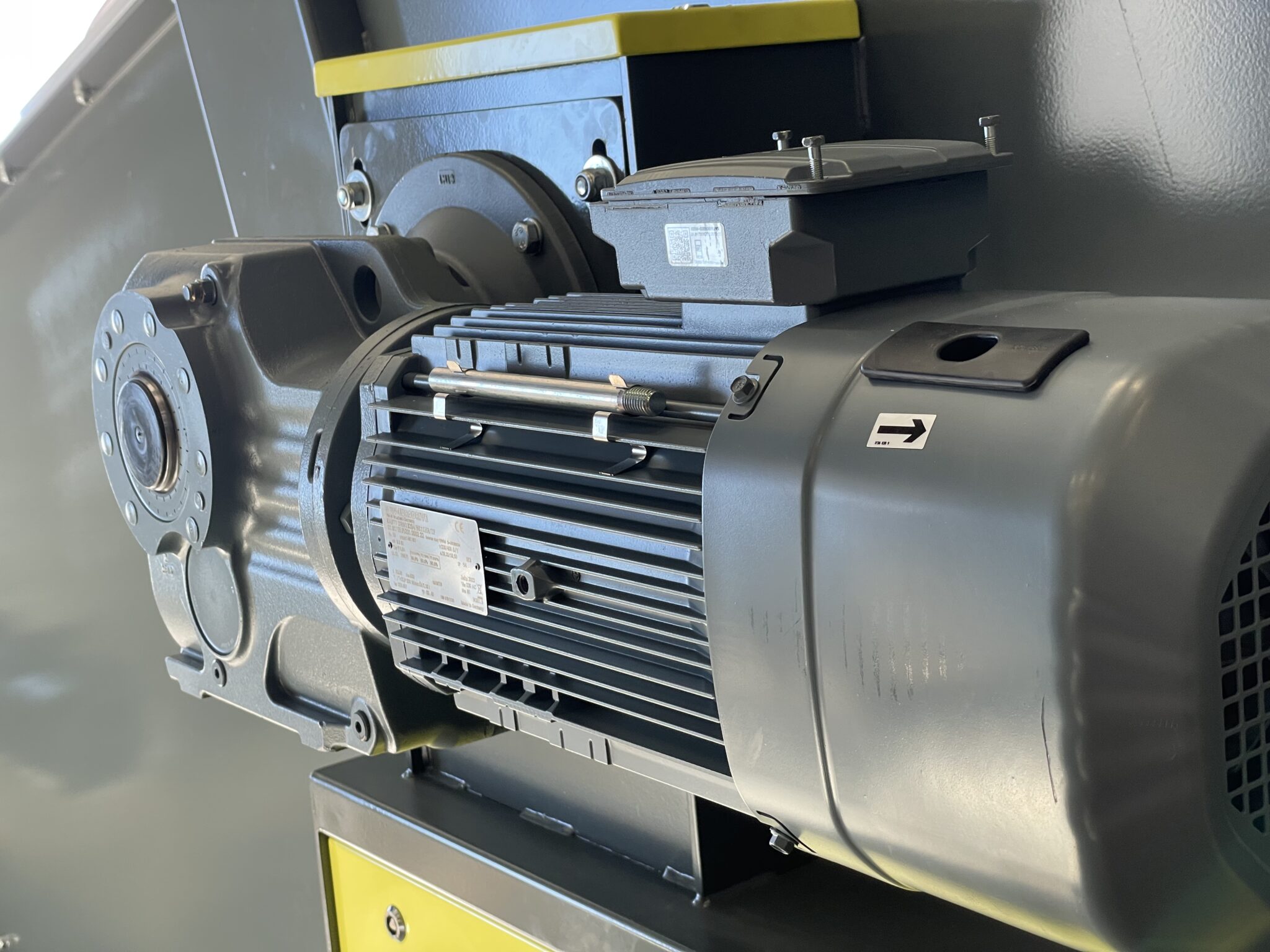

several transport screws have been delivered and installed at a milling facility specialized in biomass pelletization.

These screws will transport several types of biomass like straw, grass clippings or cocoa remnants.

This OCC screen has been delivered to Latvia. Here it will separate cardboard from other waste and ease the recycling process.

This 60m3 bunker has been installed at a Swedish recycling plant. Along with 4 screw conveyors it will store and transport shredded EV battery’s. The purpose is to extract the valuable metals and recycle them.